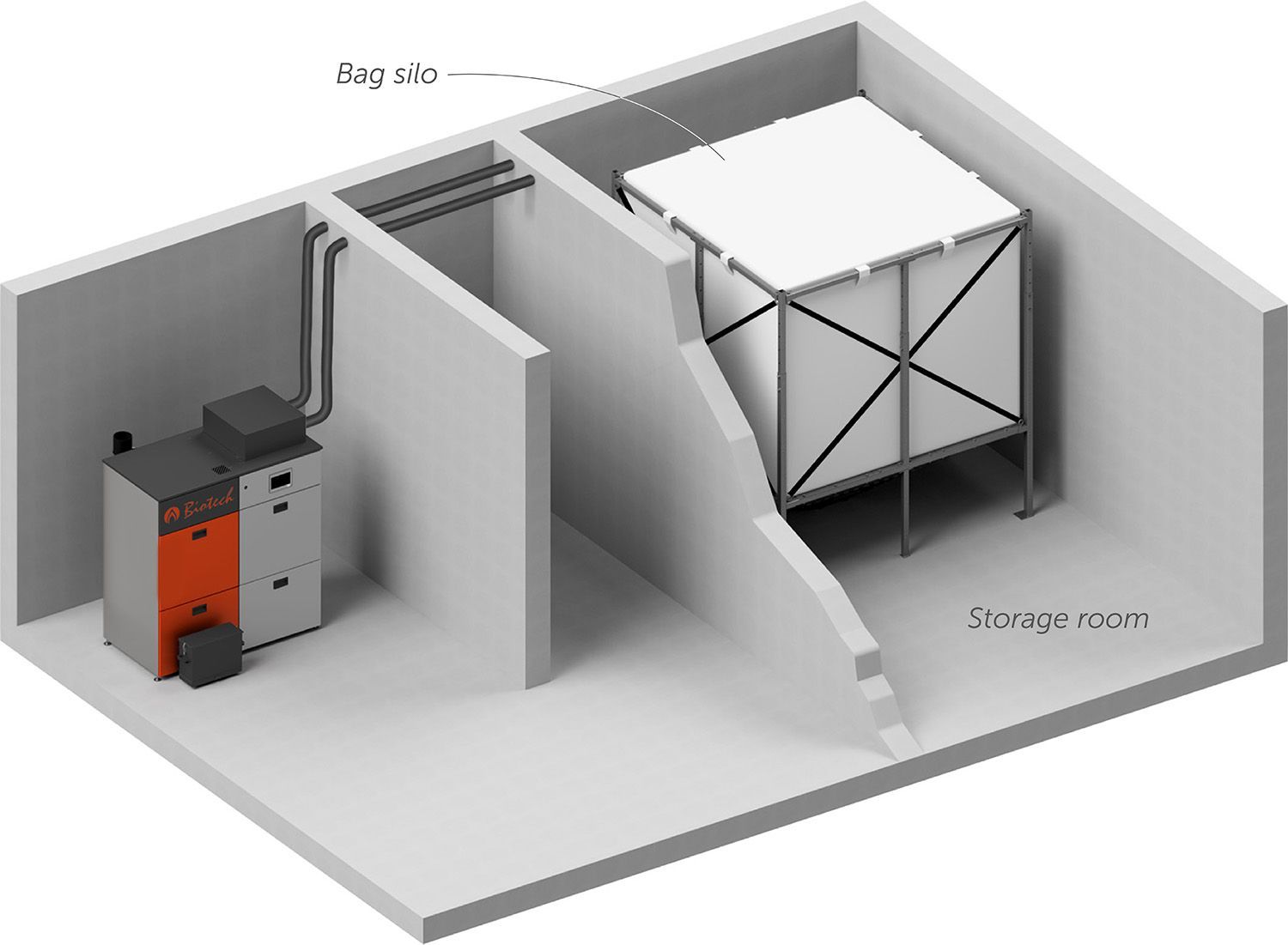

Storage in sack silos

Storage in a sack silo is particularly suitable for smaller pellet boilers whose pellet consumption is not too high. Depending on the boiler, the size of the bag silo must also be adjusted in order to be able to optimally use this convenient storage system.

The pellets are sucked into the storage container via a point suction system, which is located in the flanged removal box under the bag silo. When using a bag silo with an auger installed in the removal box, the pellets are metered into the suction hose via the auger. The sack silo is filled with pellets via the filling nozzle attached to the steel frame. Different silo sizes are available depending on the room size.

A notice:

It should be noted that the PZ100RL can consume over 400kg of pellets per day in full-load operation. Sack silos with a correspondingly small filling volume, eg only 5 tons, must therefore be filled frequently or several times per heating season and are therefore unsuitable. Furthermore, some silo manufacturers prescribe cleaning, for example after every third emptying of the silo. This would also be necessary several times a year and therefore not recommended.