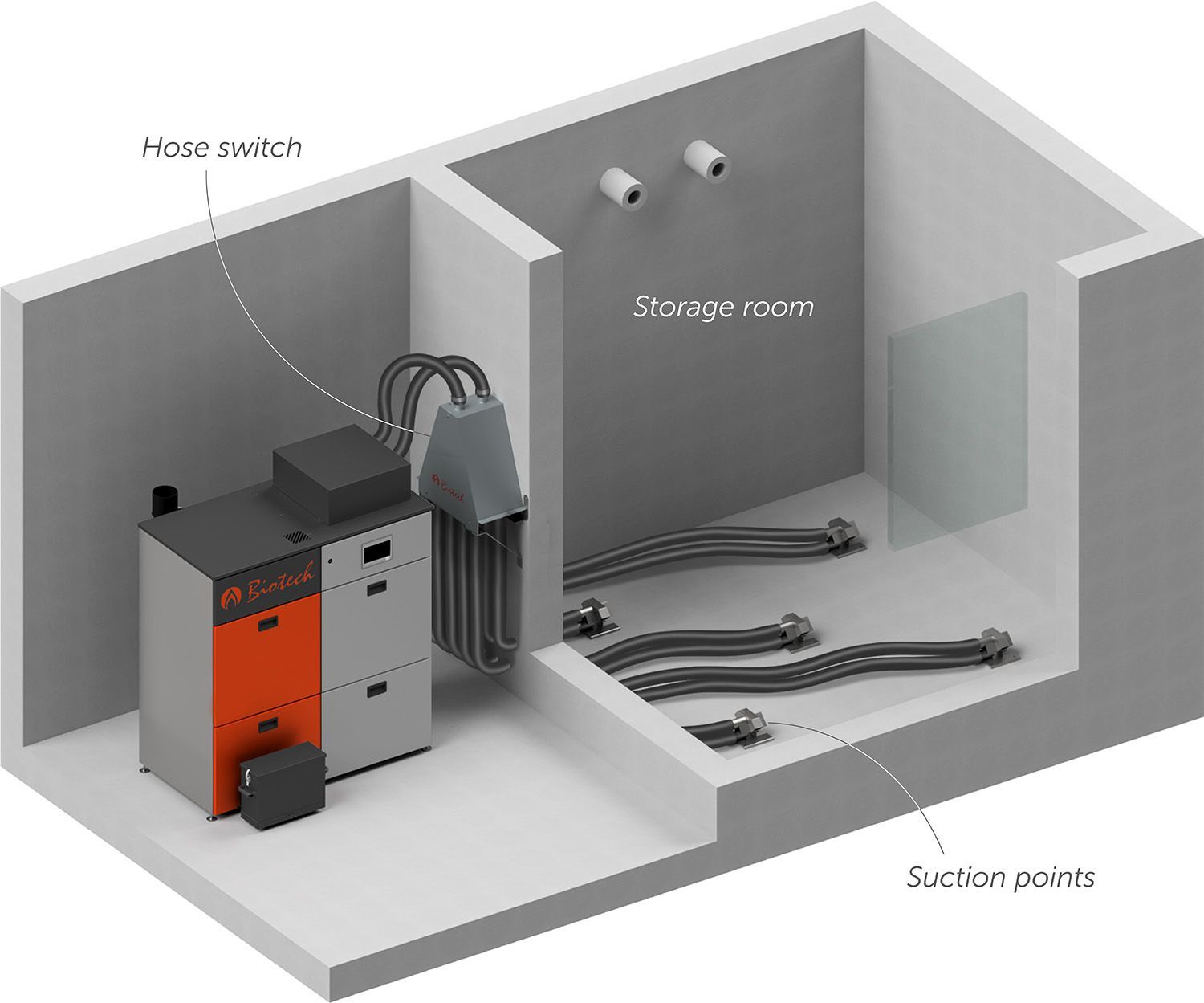

Discharge with suction points

One possible way of discharging the pellets is by suction points. These must be distributed in the middle of the room. The pellets are sucked in and gently drained via hoses and transported to the boiler. In order to use this type of discharge, a hose switch (3-fold or 5-fold) is required. These are available in automatic or manual versions. The automatic hose diverter switches independently between the suction points, while the manual one has to be operated with a lever.

There are two modes of operation:

1. Punctual mode of operation

The suction points are controlled here one after the other. Only when a suction point has been completely emptied is the next used until the store is emptied.

2. Smooth operation

The hose switch switches between the various suction points and thus enables the pellet store to be emptied evenly.

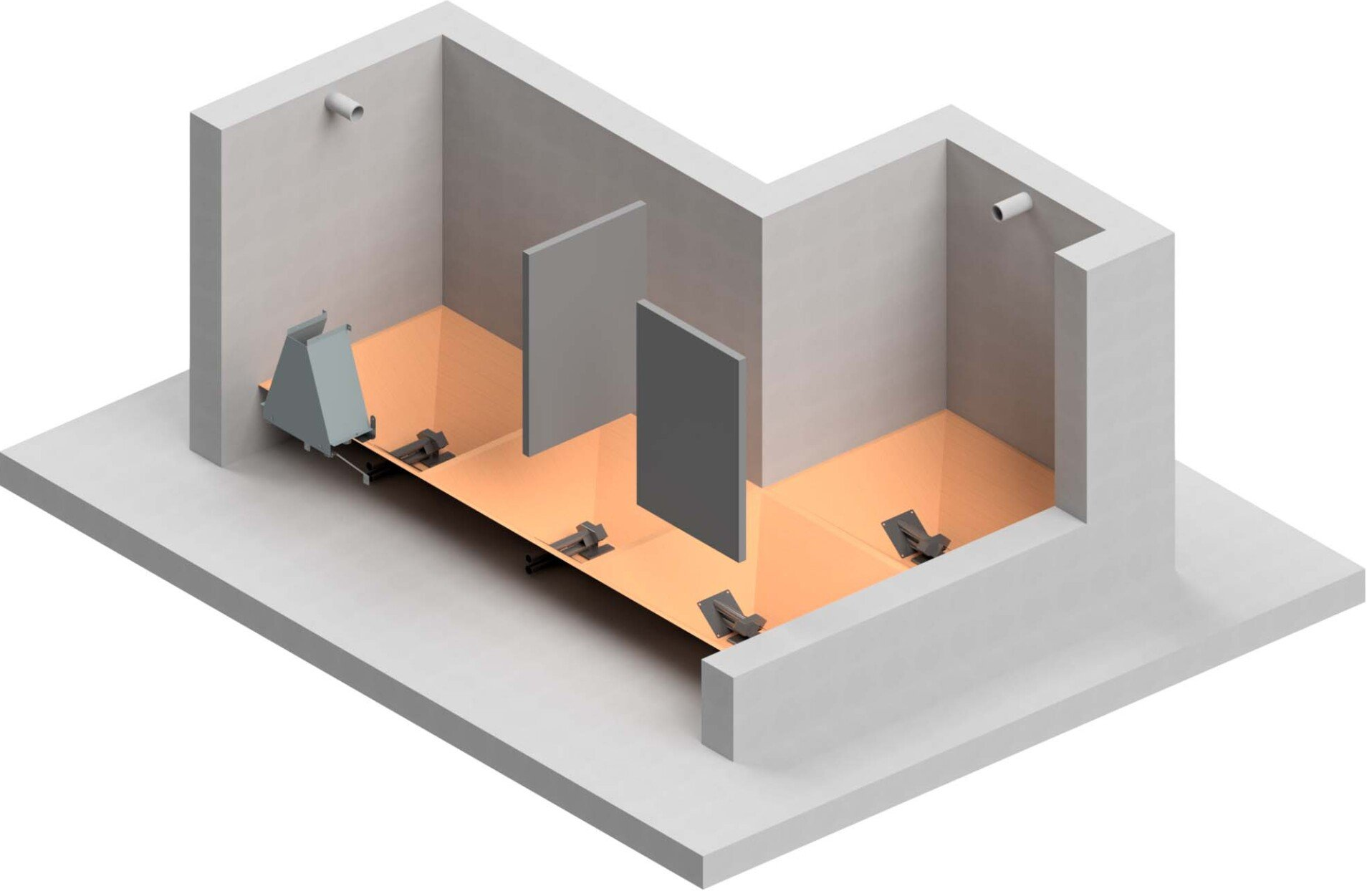

Suction point floor

Sloping floor suction point

Sloping floor 45°

In the case of discharge using extraction points, it is advisable to install a sloping floor in the storage room. This must be at an angle of 45° to ensure that the pellets slide down safely. The sloping floor allows the pellet store to be completely emptied.

A storage room with a sloping floor requires special suction points that are necessary for this type of storage.